Here Is How SEA Compatible In Handling With Every Jewellery Manufacturing

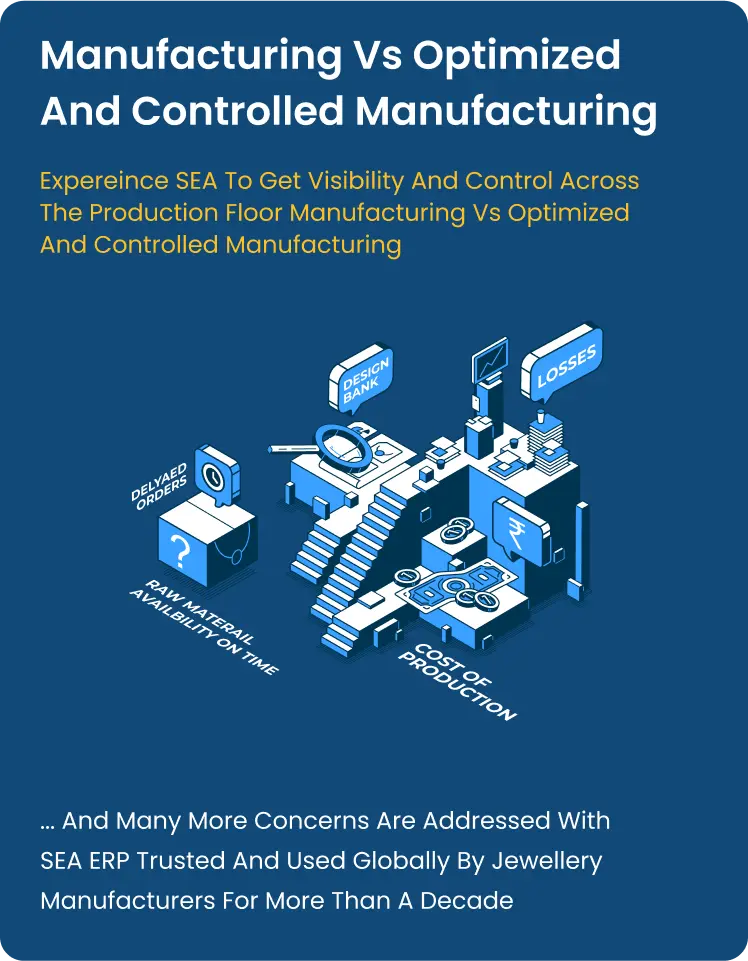

A jewelry ERP software is crucial for a wholesale jewelry business as it provides streamlined inventory management, efficient order processing, improved financial management, effective production planning, streamlined supply chain management, accurate pricing and costing, and comprehensive customer relationship management. It helps optimize operations, reduce costs, enhance productivity, and ensure customer satisfaction, ultimately leading to increased profitability and business growth.

- Diamond

- Gold

- Silver

- CZ

- Chain

- Coins

SEA Manufacturing Is The Best! But Why?

Easy usage:

Jewellery manufacturing software is a cakewalk for anyone, as it is vividly built on an intelligent self-guiding system. The advanced collaboration with Google Sheets is handy for entering the data and the exchange, making usability much more viable. The scheduling and rescheduling option ensures a user-definable report builder for the jewellery manufacturers. This is not it, and it comes with some of the perks such as monitoring the employees, user-definable umpteen combinations, catalogue management, pricing dynamism concerning the customers, and having control over procurement.

Ease of Use

Jewellery manufacturing software is a cakewalk for anyone, as it is vividly built on an intelligent self-guiding system. The advanced collaboration with Google Sheets is handy for entering the data and the exchange, making usability much more viable. The scheduling and rescheduling option ensures a user-definable report builder for the jewellery manufacturers. This is not it, and it comes with some of the perks such as monitoring the employees, user-definable umpteen combinations, catalogue management, pricing dynamism concerning the customers, and having control over procurement.

Tracing and control of inventory:

Our ERP software enables you to perform a variety of operations such as tracing every item, loss tracking, recovery management, precision casting with gold requirements, & inventory management & valuation for gold, findings, stones, chains, consumables, & finished jewellery. SEA ERP software also show you cost of items sold with a single click, even in most complex manufacturing scenarios. That's why it's the best jewellery chain manufacturing software.

Inventory Control & Tracking

Our ERP software enables you to perform a variety of operations such as tracing every item, loss tracking, recovery management, precision casting with gold requirements, & inventory management & valuation for gold, findings, stones, chains, consumables, & finished jewellery. SEA ERP software also show you cost of items sold with a single click, even in most complex manufacturing scenarios. That's why it's the best jewellery chain manufacturing software.

Secured & Seamless Operations :

Being one of the best Jewellery Manufacturing ERP software & retail jewellery software in India, Synergics comes with a variety of advanced technical features, including RFID & barcode compatibility. It also protects system with OTP, whitelisted IPs, roles & a detailed audit trail. It can be integrated with several third-party tools and services, including Qlik, SalesForce, EDI, QuickBooks, & Tally. The software also has provisions for data exchange.

Secured & Seamless Operations

Being one of the best Jewellery Manufacturing ERP software & retail jewellery software in India, Synergics comes with a variety of advanced technical features, including RFID & barcode compatibility. It also protects system with OTP, whitelisted IPs, roles & a detailed audit trail. It can be integrated with several third-party tools and services, including Qlik, SalesForce, EDI, QuickBooks, & Tally. The software also has provisions for data exchange.

Integrated Business Solution:

SEA Software for jewellery manufacturing is a fully integrated manufacturing solution that includes everything from sketch bank to production and financial accounting. It also has international automation capabilities, including multi-company features, multi- location, multi-currency support, and consolidation. SEA ERP system also includes a wholesale, retail, and web-front extension of the manufacturing setup. Moreover, you can also generate full-fledged exports and manage orders. Need Help? Chat with us

Integrated Business Solution

SEA Software for jewellery manufacturing is a fully integrated manufacturing solution that includes everything from sketch bank to production and financial accounting. It also has international automation capabilities, including multi-company features, multi-location, multi-currency support, and consolidation. SEA ERP system also includes a wholesale, retail, and web-front extension of the manufacturing setup. Moreover, you can also generate full-fledged exports and manage orders.

How synergics helps execute jewellery manufacturing

Get A Free

DEMO

Speak with our ERP software experts to discuss your jewellery business goals, needs and timeline today !